How to Regrease a Thrustmaster TWCS Throttle

The standard grease used in the Thrustmaster TWCS Throttle is not as smooth it could be. For better control, use Nyogel 767A instead.

Page Contents

Introduction

The standard grease requires a little bit of extra traction to get the throttle handle to move than it does to keep it moving. Because of this, fine control is hard to attain. For example, I’ve read that this can really mess up air to air refuelling in DCS which requires a high level of precision. Even in normal use, compensating for this asymmetric traction requires effort that isn’t realistic or rewarding, but is solved quite easily.

There are kits you can buy that will replace the moving block and rail bearings, but that solution is more expensive and requires going into disassembling the block. Since regreasing the rails is much less invasive, I made it my first thing to try, and as far as I’m concerned I have no need to go any further. Regreasing with Nyogel 767A achieved the result I wanted.

Nyogel 767A Grease

The preferred type of grease rated by many is called Nyogel 767A. It is very expensive to buy in quantity, but you may be able to buy a small amount from a supplier on eBay. The amount shown here is 1g, but you will only need a few percent of a 1g blob to do a thorough job.

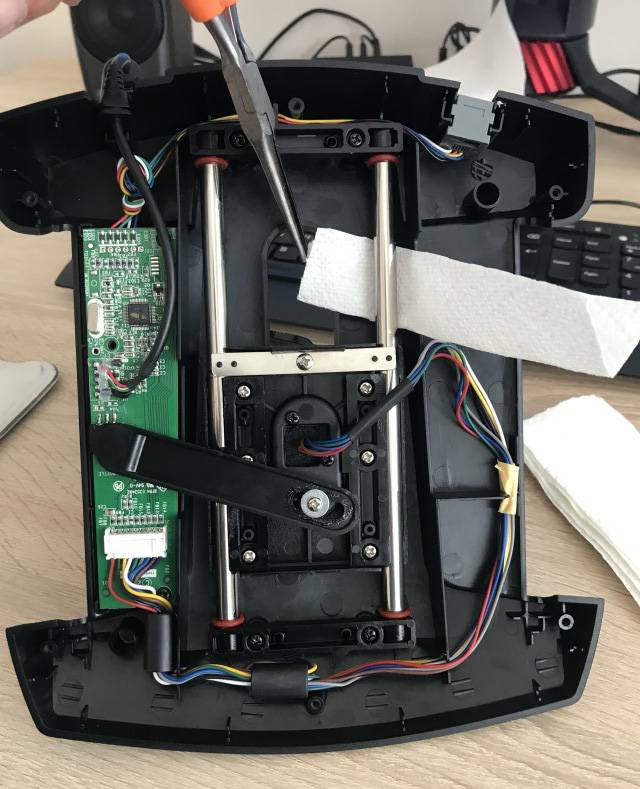

Useful Tools

You can do the whole job with just a screwdriver and your finger, but you may find it useful to have some tweezers (pliers in this photo) and a paintbrush to grease the throttle lever.

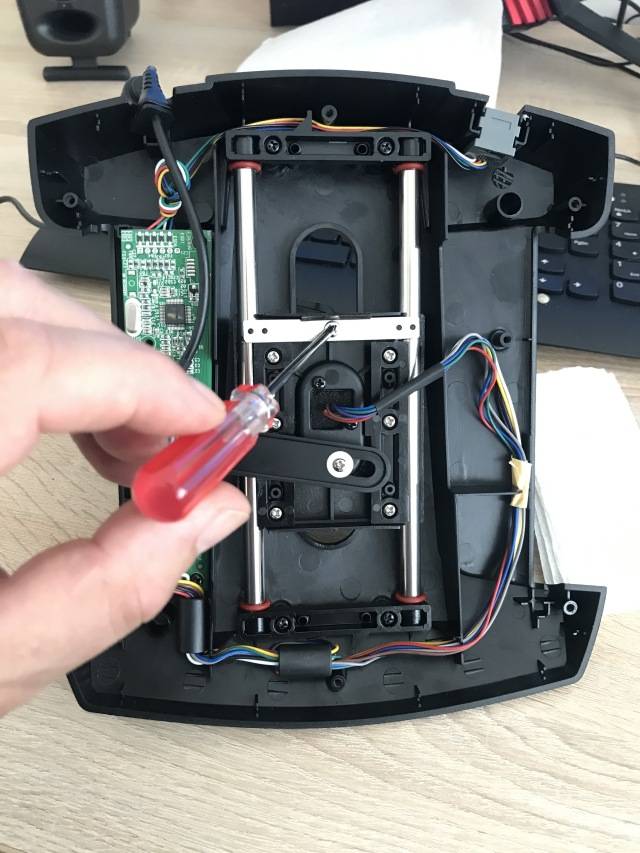

Unscrew the Base

This is the underside of the throttle.

- Take note of how the USB cable looks at the exit of the housing so you can easily reassemble it later on.

- The screw you can see below the centre-top screw is the tension adjusting screw that alters the friction on the throttle. Be sure to avoid accidentally tightening this screw when you reassemble the throttle later.

Clean the Guide Rails

Get a sheet of thick paper towel and cut it into strips. Open up the back of the throttle and pull a strip under one of the rails to begin taking off the original grease.

Move the throttle up and down to access all parts of the two rails and to expose grease hidden inside the moving block.

Clean the Swinging Arm

You will then need to clean out the grease from the top of the swinging arm by moving the block up and down to expose different areas of the arm.

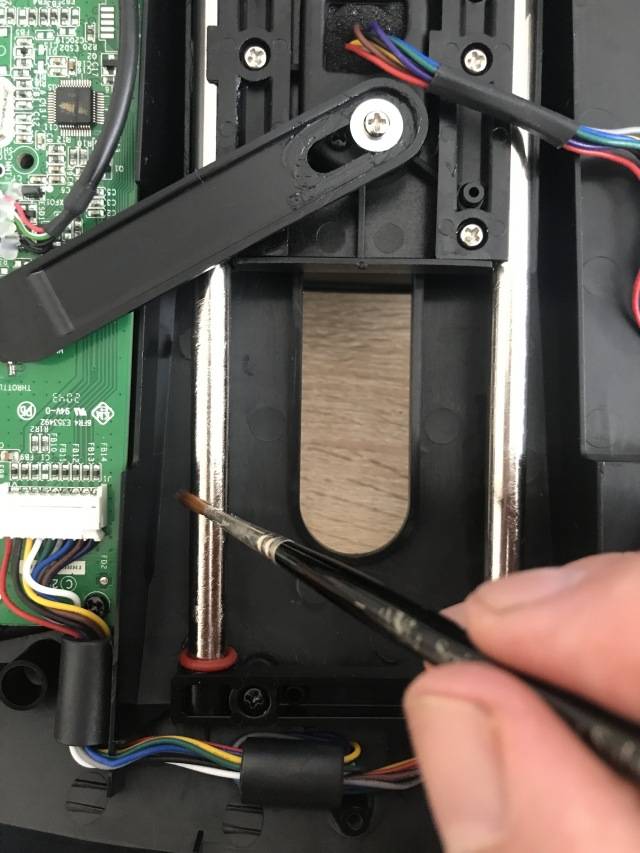

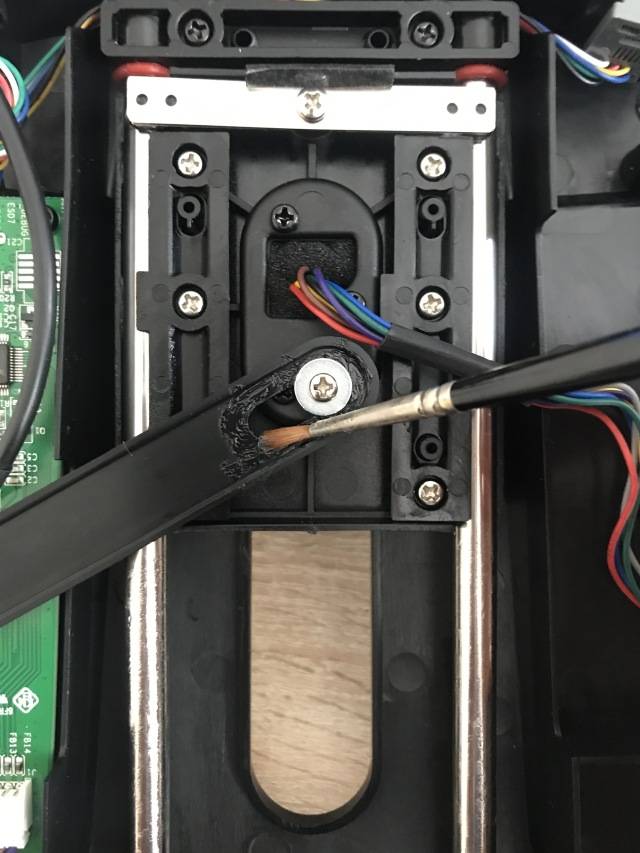

Apply Nyogel 767A

When all the standard grease is removed, you can begin applying the Nyogel 767A. Initially I used a paint-brush as shown, but the Nyogel is really stiff, so I ended up applying it with a small flat bladed screwdriver to apply it to the rails and and my finger to even it out. Don’t miss the underside of the rail. Do not leave any blobs behind – you will need to leave it with a thin even layer if you can.

I found the paint brush useful to apply Nyogel 767A to the swinging arm where the indent was too small for my fingertip to access easily.

Despite my best efforts, this grease is so stiff that I can’t apply it neatly. However, the movement of the arm will smooth out the grease to where its needed.

Set the Throttle Tension

At this point you can move the throttle back and forth to even out the lubrication and then adjust the tension in the throttle friction arm using the same screwdriver as before. Since the unit is uncovered its easier to see the effect of an adjustment as well as feel what it does. Flip the throttle onto its base and try it out your settings until you get it just right.

Reassemble

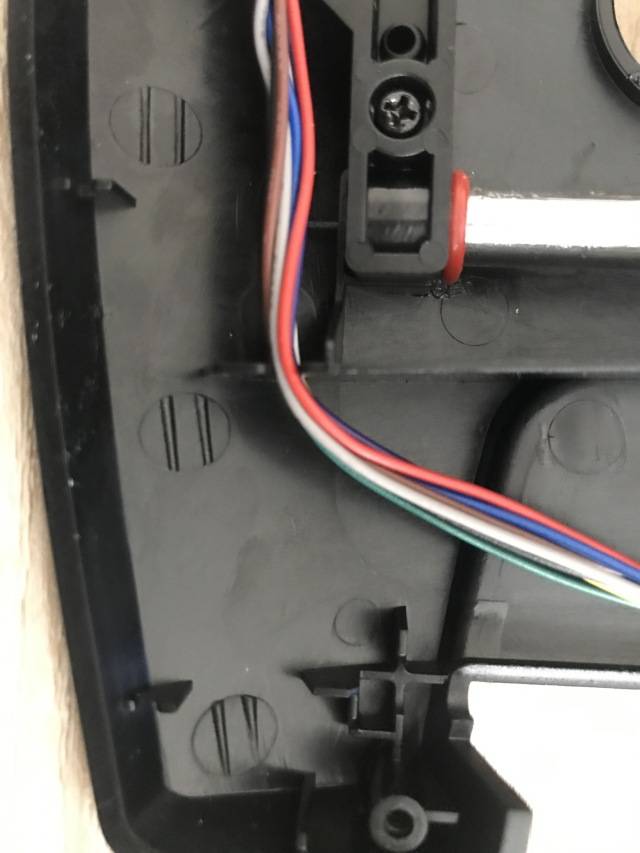

When you are ready to reassemble the base plate, check the wiring to make sure that it is sat neatly in the clips provided in the base plate.

Similarly, ensure the USB cord is positioned in its holder at the exit of the base plate. It isn’t fixed into place until you have screwed the base plate back on. The two halves clamp the USB cable somewhere near the middle of the conical shape, not the end.

When you reassemble the throttle, there is a possibility that you may mistake the tensioning screw for one of the baseplate screws, so take care to avoid that trap.

Adjust Throttle Tension

With the whole thing reassembled, you will notice that the Nyogel 767A is a fairly stiff grease that provides a constant resistance for long movements, and for fine movements the resistance is not high, and may even offer some stability. You can optimise this resistance with the tensioning screw underneath the throttle. Move the throttle to its fully-forward position to make the tensioning screw visible in the baseplate hole.